Process - description

1) Making cast mould

2) Making wax pattern

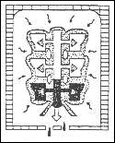

3) Assembly wax pattern

4) Dip into slip

5) Shifted with grain

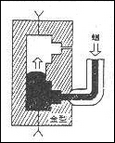

6) Melt out (lost wax)

7) Sintering

8) Casting

9) Cutting

10) Cate stubs/Ground off

11) Inspection

12) Finished part

At the begining a permanent mould for producing the wax pattern will be made. (1). Into this mould a low temperature melting material, such as wax, will be filled in to form the pattern (2),(which is the model with the geometry of the working piece). For medium/big series several pattern are assembled together (3). This tree will be dipped into the slip (4) and cover with sand (5) in several shifts. After drying the wax will be melt out (lost wax) (6) and the mould will be sintered to achieve the required hardness. Then the material will be casted into the cavaties (8) and after cooling down the sand mould will be destroyed to take out the working pieces from which the runners/stubes are cut off (9/10) to do the final inspection (11).